Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

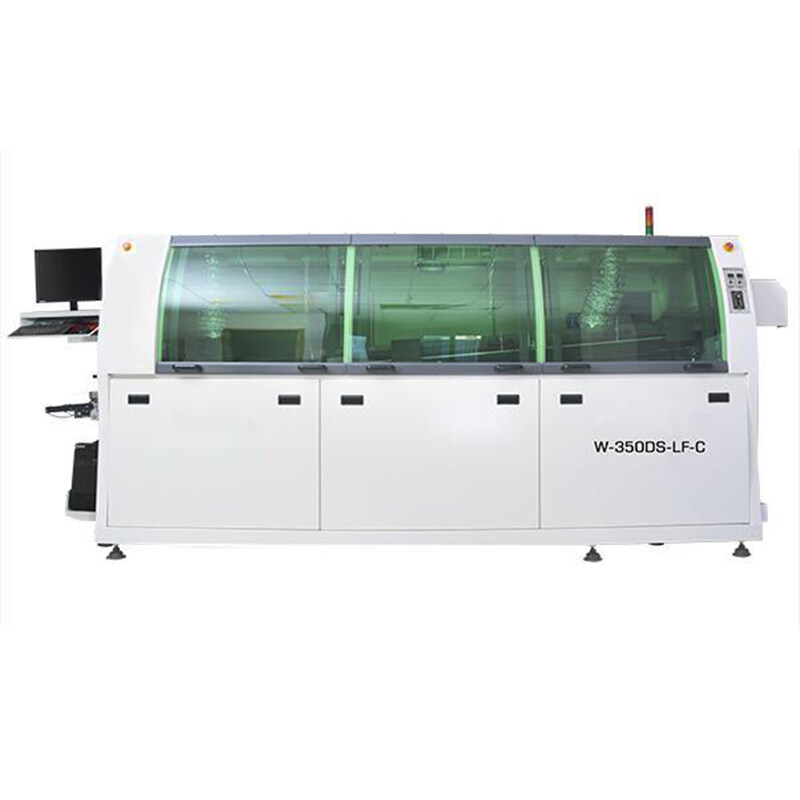

HCT-T100 Small 4 Heads SMD Pick and Place Machine

The major benefit of employing SMT machines for LED manufacturing is that hand assembly variations are completely eliminated. Multiple components are placed on the board simultaneously by the accurate and very accurate automatic led pick and place system, greatly increasing production and lowering labor costs. As human participation has been reduced, the efficiency of SMT-based LED component manufacturing has grown tremendously.

HCT - China Small SMT Pick And Place Machine

HCT is a Chinese company that specializes in the manufacturing and supply of small SMT (Surface Mount Technology) pick and place machines. These machines are widely used in the electronics industry for the precise placement of surface mount components onto printed circuit boards (PCBs).

HCT offers a variety of small SMT pick and place machines designed to cater to different production requirements. These machines are compact, efficient, and capable of handling various types of components with high accuracy and speed. They are equipped with advanced features such as vision systems for component recognition, multiple placement heads for simultaneous picking and placing, and software integration for seamless operation.

HCT's small SMT pick and place machines are known for their reliability, flexibility, and user-friendly interface. They provide precise component placement, minimizing errors and enhancing productivity in SMT assembly processes. These machines can handle a wide range of components, including resistors, capacitors, integrated circuits (ICs), and more.

As a Chinese manufacturer, HCT offers competitive pricing for its small SMT pick and place machines while maintaining high quality standards. They also provide comprehensive technical support, including installation, training, and after-sales service to ensure customer satisfaction.

Technical Parameters - Mini 4 Heads SMD LED Pick and Place Machine

|

Model |

HCT-T100 |

|

|

Number of Heads |

Fixed Bottom Vision |

4 |

|

Placement Rate |

Under the optimum condition |

6000CPH |

|

IPC9850 |

5000CPH |

|

|

Feeder Capacity |

Front and Back

|

18 Tape Feeders (Electric standard) 18+18 Tape Feeders(Optional) 25+25 Pneumatic Feeders (Optional) |

|

IC Tray Capacity |

325 x 135mm |

1 |

|

Component Alignment |

Vision Detection |

|

|

Component Sizes |

Handled by Fixed Small Camera |

Smallest: 0402 (inch) |

|

Largest: 6 x 5 (mm) |

||

|

Max. Height: 15mm |

||

|

Handled by Fixed Big Camera(Optional) |

Smallest: 5 x5 (mm) |

|

|

Largest: 20 x 20 (mm) |

||

|

Resolution

|

X/Y Axis |

Ball Screw + Servo Motor |

|

Z Axis |

Step-Servo Motor |

|

|

Rotation |

0 to 360° |

|

|

Placement Accuracy |

±0.05mm |

|

|

X-Y Repeatability |

Ball Screw |

±0.02mm |

|

PCB Size |

Maximum |

L 300 x W 250mm |

|

|

Minimum |

L 50 x W 50mm |

|

Programming |

Vision Teach-in |

|

|

Coordinates Import |

||

|

Main Control |

|

Industrial PC |

|

Power |

AC 220V±10% (50/60Hz, 1 phase) |

|

|

Max. 1.5KW |

||

|

Air Pressure |

0.55-0.7MPa (5.6-7.1kgf/cm2) |

|

|

External Dimension(mm) |

L x W x H |

700 x 900 x 1300 mm |

|

Mass |

Approximate 150kgs |

|

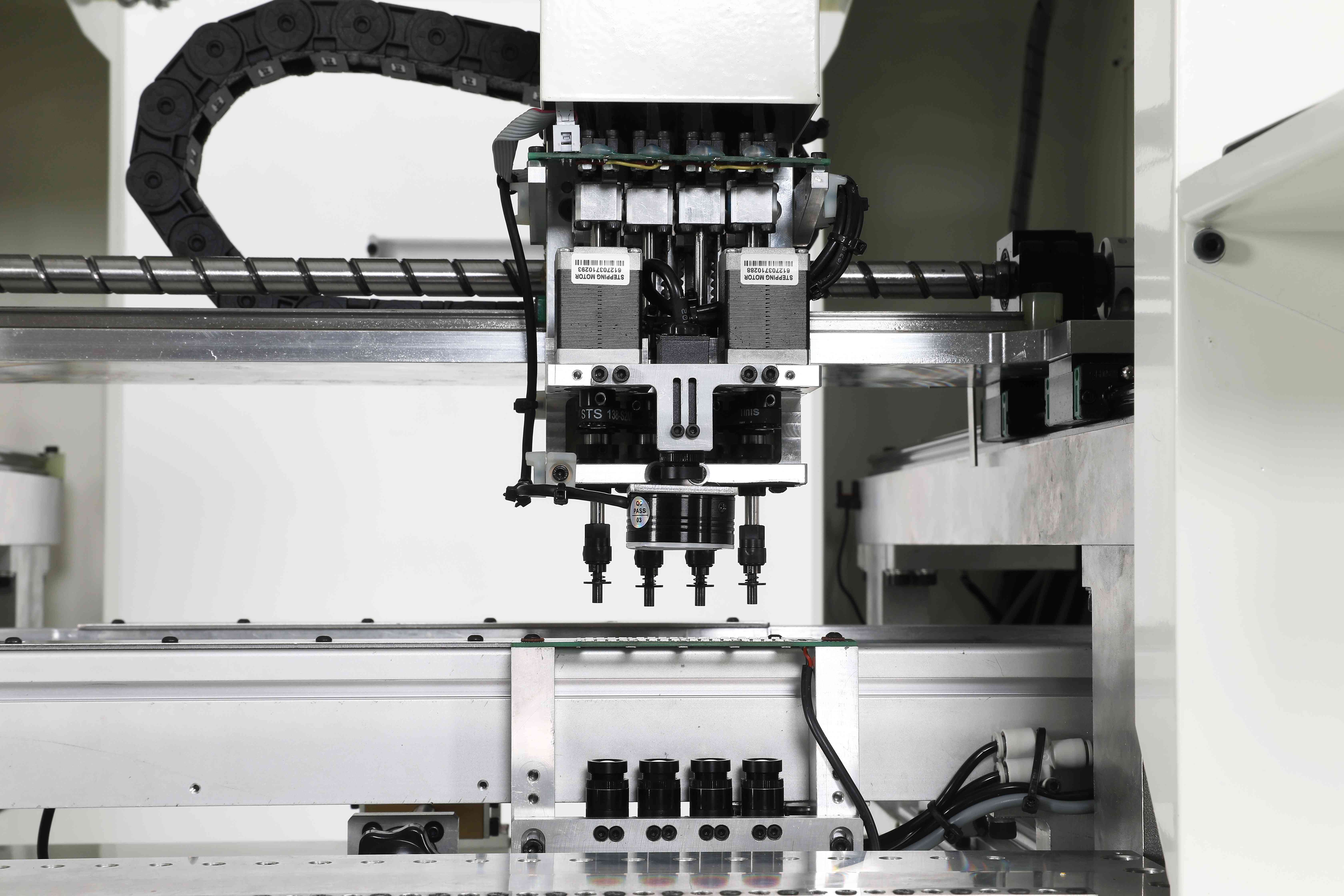

Product Features - Mini 4 Heads SMD LED Pick and Place Machine

1. Bottom Vision Alignment System.

2. Fiducial recognition and coordinate correction.

3. Conveyor system with SMEMA interface and automatic width control.

4. Perfect for proofing of production.

5. Optimized pick/place routing design, ensures precision.

6. Works with different types of the high-precision nozzle.

7. Suit for a variety of SMD components: resistors, capacitors, IC, SOP, QFP, QFN, SOT, etc.

8. Using imported high-precision ball screws, motors, solenoid valves, cables, etc., effectively improves placement accuracy, and stability.

APPLICATION AREA

SMT Proofing use & Laboratory use; Small batch production; University teaching use; R&D customization; Personal entrepreneurship; processing on giving materials; etc.

Advantages of the SMT Process for LED Pick and Place

The biggest advantage of using SMT machines for LED is that it eliminates the possibility of variations common to manual assembly. The precise and high-precision automatic led pick and place machine places multiple components on the board at once, dramatically increasing productivity while reducing labor costs. The efficiency of SMT-based LED component manufacturing has increased exponentially as a human intervention has been minimized.

In addition, to pick and place-led manufacturing, the importance of the SMT process for led pick and place is also reflected in the design process. Miniaturization is the trend in LED lighting, and the pick-and-place SMD-led mounting machine makes this possible. The LED SMT machine utilizes higher levels of automation, high-quality nozzles, and feeders, all of which combine to allow the handling of much smaller components than traditional assembly methods.

Another important aspect of the SMT LED machine that helps achieve compact dimensions is the use of zero wires. This process reduces the size of the board by mounting the components directly onto the board, resulting in a compact and slim design.

Product Display - Mini 4 Heads SMD LED Pick and Place Machine